Have you, as a financial analyst, ever sat in a meeting with Supply Chain, Engineering, Operations, and Manufacturing teams and felt like you needed a translator to follow what’s going on? Many Financial Planning & Analysis (FP&A) professionals can relate. They can understand the struggle of bringing together Supply Chain and Finance inputs to effectively forecast supply and demand as part of Sales and Operations Planning (S&OP) processes.

In fact, the responsibility usually lands on FP&A to unify the demand plan with the financial plan. But without cross-functional inputs from the Operations, Supply Chain, and Manufacturing functions, this responsibility can be a massive challenge. However, the cross-functional inputs are an essential piece of the puzzle when elevating traditional FP&A software processes for eXtended Planning and Analysis (xP&A).

What Is S&OP?

Sales and Operations Planning is a process by which organizations forecast demand, supply, and financial plans to enable supply chain management. While collaboration between the Operations and Finance functions has improved, there are still significant disconnects that result in a financial plan that doesn’t paint the complete picture of the enterprise.

Capturing these inputs within FP&A software does, however, give the whole picture. The software helps align the organization by leveraging inputs beyond Finance that more effectively prepare the business to operate in turbulent market conditions.

How Does the S&OP Process Typically Work?

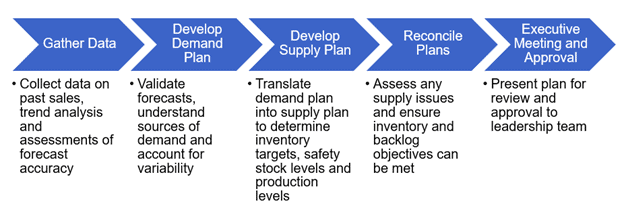

The S&OP process is typically run on a monthly cadence. To start, the process involves data gathering and then moves through the demand and supply plans, plan reconciliation, and, finally, meetings and approvals (Figure 1).

Effectively leveraging the S&OP process to inform xP&A planning cycles gives an organization better insight into the plan beyond just the numbers. In the xP&A process, leveraging these S&OP insights is important, and doing so in the most effective fashion is enabled by unifying the planning processes in a shared software environment. Here are just a few examples of why unifying S&OP and xP&A processes are so critical to consider within FP&A software:

- When FP&A software is used for the S&OP and xP&A process, the analysis of data is faster and more accurate within the same software platform when compared to using multiple Excel spreadsheets or a siloed application environment.

- Data quality and accuracy are higher when planning is performed in one system, providing the most timely and accurate information to many users in the organization to support better collaboration.

- Comparing actuals to the forecast and plan is faster and more reliable when the data is available in one unified system, and forecasts are more quickly adjusted.

When FP&A isn’t part of the S&OP process, there’s often a disconnect between operational planning and the financial impact of the related decisions. Balancing supply and demand impacts Finance as the balance influences revenues, cost of goods sold, profit margins, inventory carrying costs, headcount, cash flow, working capital, and various other financial metrics.

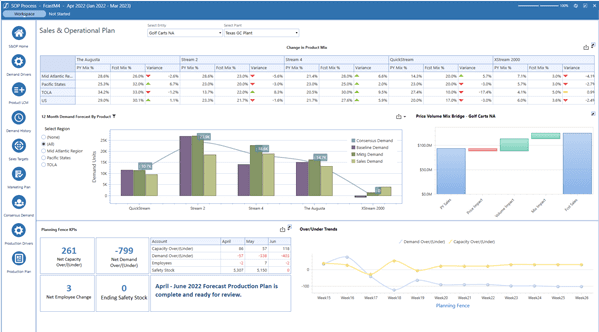

What happens when supply and demand aren’t balanced? Well, when suppliers can’t deliver on time, it not only affects the organization’s ability to meet customer needs but also influences other non-financial metrics that are important to Finance. Understanding these intricacies of the S&OP process can help Finance to develop a financial plan that takes these S&OP factors into account. At the same time, Finance can lend insights into the process as it’s happening to ensure complete integration into the financial and operational plans (see Figure 2).

Incorporating the S&OP sales and demand planning outputs into the financial planning process provides, among others, two key benefits. First, organizations can better understand the supply chain and operations impacts. Second, organizations can also sense potential disruptions in supply chains and issues in manufacturing and labor availabilities. These benefits are especially crucial in a post-pandemic new normal. To remain competitive, FP&A must move away from a functional process and move to a business process that encourages collaboration and cross-functional integration of supply chain, sales, operational and financial data.

The new normal ultimately requires companies to be more agile and efficient than ever to react to real-time disruptions. The ability to do so requires ensuring the insights and reporting gained from forecasting cycles are shared across the organization. In turn, that capability enables the organization to better react to labor shortages and fluctuations in the availability of raw materials and resources that would otherwise slow or stop production amid high demand.

Key S&OP Metrics for FP&A

The S&OP process has both financial metrics as well as demand and supply metrics, and the financial metrics are important to incorporate into the financial planning process. Here are some of those key financial metrics:

- Total Sales: Since S&OP deals with demand and supply forecasts, total sales data will help assess the financial health of the organization.

- Gross Margin: The goal is to have total sales meet projected targets, but just as important is ensuring that the gross margin is meeting projections.

- Working Capital Projections: It’s essential to check that the organization has as much working capital available as the team forecasted. If the number falls short, it might be time to evaluate why and adjust projections.

Why Effective xP&A Must Unify FP&A & S&OP

During the S&OP process, the financial implications of the decisions are vital considerations, but the exclusion of Finance means these decisions are often overlooked. Ensuring that the financial perspective is considered during the development of the demand and supply plans lends weight to the decision-making happening as part of the S&OP process.

Conversely, if Finance is preparing the demand plan as part of the FP&A process without Supply Chain buy-in, there will be frustration from both groups. Why? Because they’ll be operating on different assumptions and understandings of the organizational objectives.

Conclusion

Ultimately, FP&A is not only a key input to the S&OP process but also a consumer of the output. It’s just as important for Finance to be involved in the process as it is for the output to inform the FP&A, and now xP&A, planning cycles. Understanding the financial implications of the demand and supply plans developed as part of the S&OP process helps align organizational goals – from both a Finance and Supply Chain perspective.

Learn More

To learn more about how your organization can grow your FP&A process to xP&A, click here to watch a video on the 5 Key Factors to Consider in the FP&A Evolution to xP&A.

Get Started With a Personal Demo